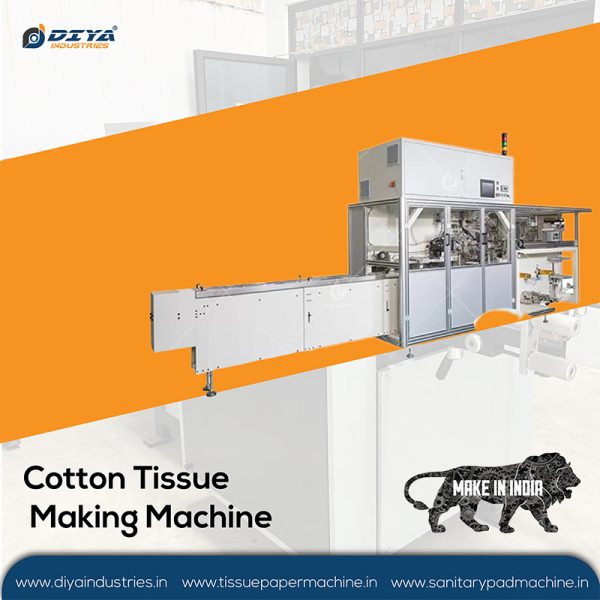

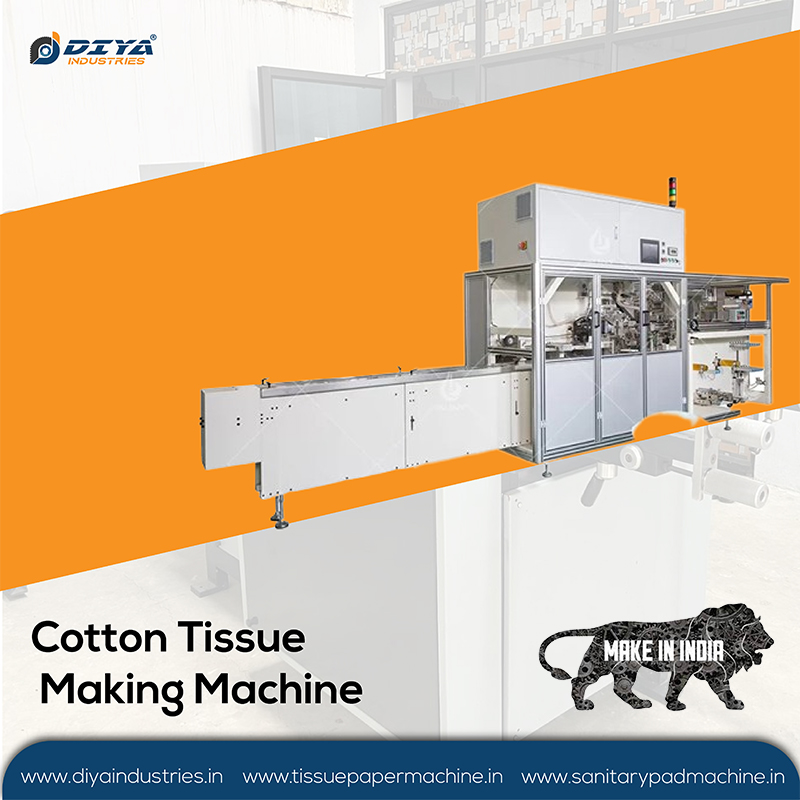

Cotton Tissue Making Machine

Cotton tissue making machines are used to produce cotton tissue or cotton pads, which are commonly used in personal care, cosmetic, and medical applications. These machines are designed to convert raw cotton into finished cotton tissue products.

- Description

- Reviews (0)

Description

- Raw Material Preparation: Raw cotton is first cleaned and processed to remove impurities and foreign materials. The cotton fibers are then carded and formed into a thin layer.

- Cotton Web Formation: The carded cotton fibers are fed into a machine that forms a continuous cotton web. This web is usually made by a combination of carding, cross-lapping, and air-laying techniques.

- Cutting and Folding: The continuous cotton web is then cut into individual sheets of the desired size. These sheets are typically square or rectangular. The machine can also fold the sheets to create multiple layers of cotton tissue.

- Packaging: The cut and folded cotton tissues are then packaged into suitable containers, such as boxes or plastic bags. The packaging process may involve automated systems or manual labor, depending on the scale of production.

- Optional Additions: Some cotton tissue making machines may include additional features or modules for adding functionalities to the cotton tissues. For example, machines used in the cosmetic industry may have the capability to apply lotions, oils, or other cosmetic substances to the cotton tissues during the manufacturing process.

Reviews

There are no reviews yet.