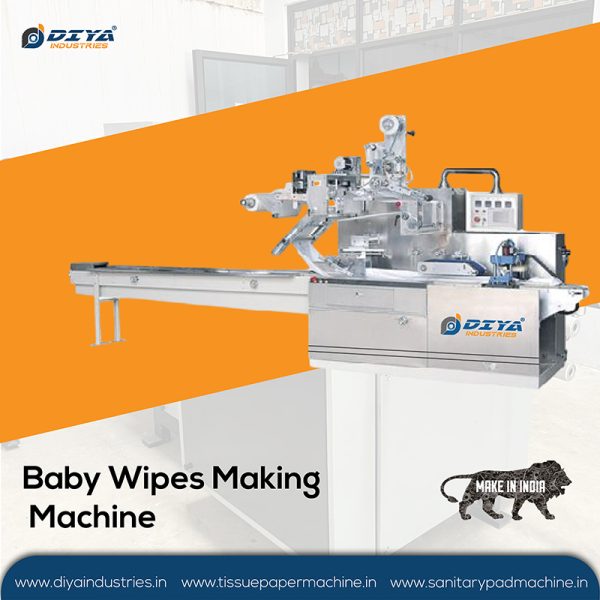

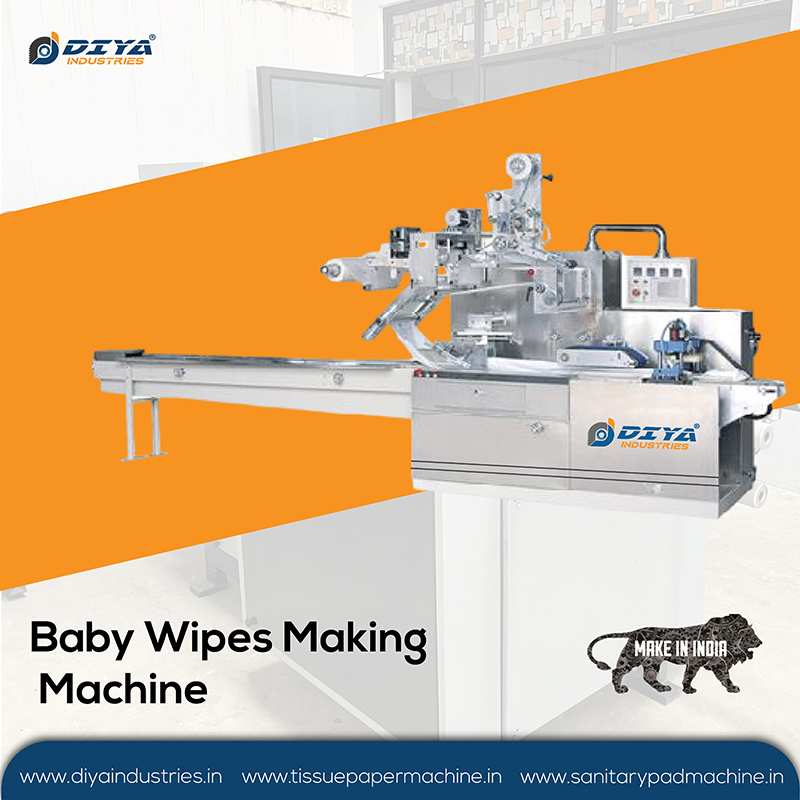

Baby Wipes Making Machine

A baby wipes making machine is a specialized equipment used in the manufacturing of baby wipes or wet wipes. These machines are designed to automate the production process, allowing for efficient and consistent production of high-quality wipes.

- Description

- Reviews (0)

Description

- Unwinding system: This system unwinds the base material, usually a non-woven fabric or spunlace material, from a roll. The material is fed into the machine for further processing.

- Moistening system: Baby wipes require moisture to be effective. The machine includes a system that applies the desired amount of water or a gentle cleansing solution to the base material. This can be done using sprayers, nozzles, or other methods.

- Folding and cutting mechanism: The machine is equipped with a folding system that folds the wet material into the desired size or shape. It can be a simple single-fold or a more complex multi-fold design. After folding, a cutting mechanism trims the material into individual wipes.

- Packaging system: Once the wipes are cut, they need to be packaged for distribution. The machine may have a packaging system that wraps the wipes in airtight packaging, such as plastic bags or containers. It can also include a sealing mechanism to ensure the wipes remain fresh and moist.

- Conveyor system: A conveyor system is often present to transport the wipes through the various stages of production. It ensures a smooth and continuous workflow.

- Control panel: The machine is controlled through a central control panel, which allows operators to adjust parameters such as moisture levels, folding patterns, cutting sizes, and production speed

Reviews

There are no reviews yet.