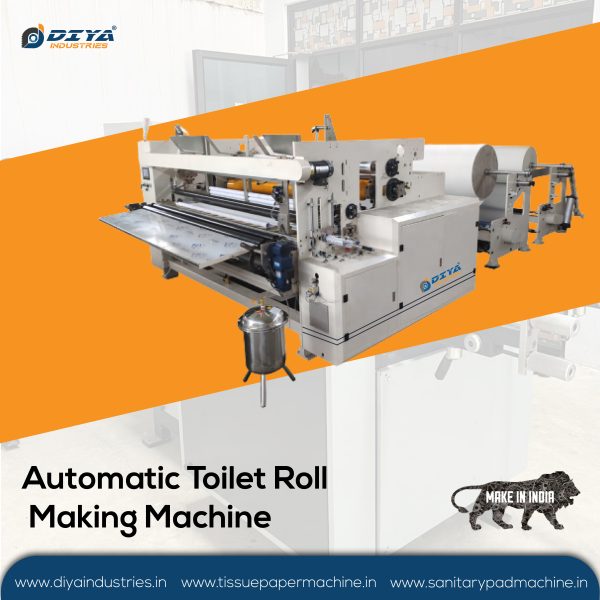

Automatic Toilet Roll Making Machine

An automatic toilet roll making machine is a highly advanced and efficient piece of equipment designed to automate and streamline the entire process of manufacturing toilet rolls. It is a fully automated solution that offers exceptional productivity, precision, and reliability.

This machine is equipped with advanced features and components that eliminate the need for manual intervention, ensuring a seamless and continuous production process. It includes a paper unwinding system, cutting and perforation mechanisms, embossing unit, winding system, and packaging capabilities.

- Description

- Reviews (0)

Description

As Per Following Specification,

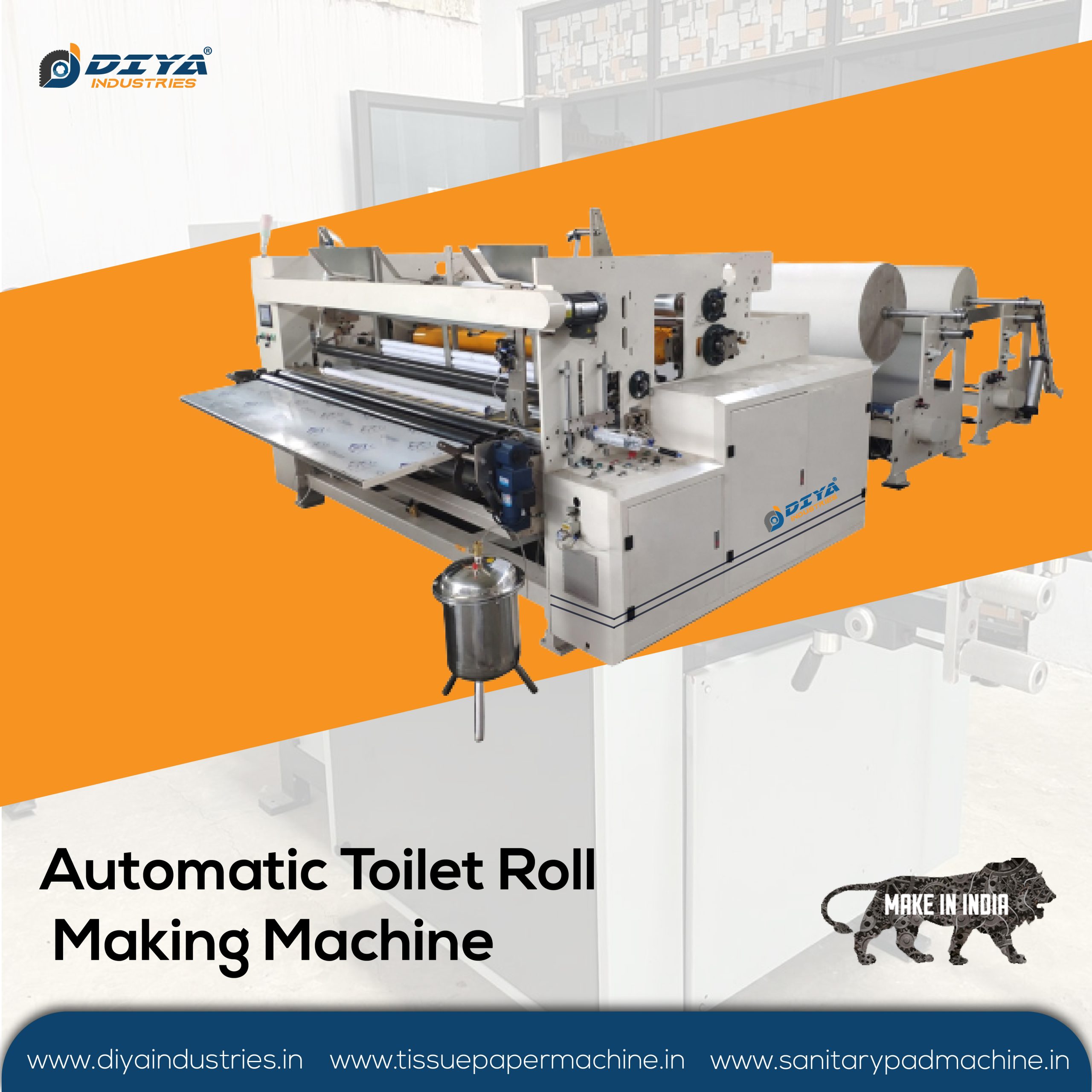

MODEL-L-WING SUPER-14 ROLL

- Maximum Paper Width : 1420mm

- Maximum Unwind Diameter : 1200mm

- Maximum Rewinding Diameter : 254mm

- Parent Roll Core Inner Diameter : 76mm

- Raw Material : 1 or 2 Layer Tissue Paper

- Reel Unwind Unit : Two

- Perforation repeat : 100mm

- Embossing unit : One ( metal to rubber)

- Power Consumption : 5 HP ( Three Phase )

- Control : PLC With Frequency Drive

- Production / 8 hr. : 800-850 logs of 100 gsm approx 12000-15,000 toilet roll of 4 inch

- Weight : 3000 Kg (Approx)

- Machine Dimension : 10L x 9W x 6.5H (Ft.) Approx

- Automatic paper cutting and gumming after rewinding.

- Variable Speed Pully Drive for control the jumbo roll speed.

Reviews

There are no reviews yet.